JBFM SERIES

2 Piece Floating Ball Valve, Metal-Seated

JDV is proud to offer the JBFM Severe Service Ball Valve. These are the newest products in the JDV portfolio, and JDV has completed this new cutting edge product with Computer-Aided Drafting & Design, Finite Element Analysis, verified and validated by prototyping and extensive design testing in its Research & Development Center. The result is a robust, thoughtful, feature-rich design that we are confident will exceed the expectations of even the most demanding valve users.

Specifications

JBFM Series Metal-Seated Ball Valves

Size Range

NPS 0.5 – NPS 8

Temperature Range

-320°F (-196°C) / +1,000°F (538°C)

Design Standard

Valve Design: ASME B16.34, API 608 (Standard) API 6D (Option)

Valve Test: API 598 Shell, ANSI/FCI 70-2 Class VI Shutoff (Standard), Zero Leakage Shutoff (Option), API 6D Test (Option)

Actuator Mounting: ISO 5211

Body Materials

Carbon Steel: WCB, LCC

Duplex Stainless Steel: CD3MN

Stainless Steel: CF8M, CF8, CF3M, CF3, CG8M

Other Materials Available on Request

Pressure Class Range

ASME Class 150, 300, 600, 900, 1500, 2500

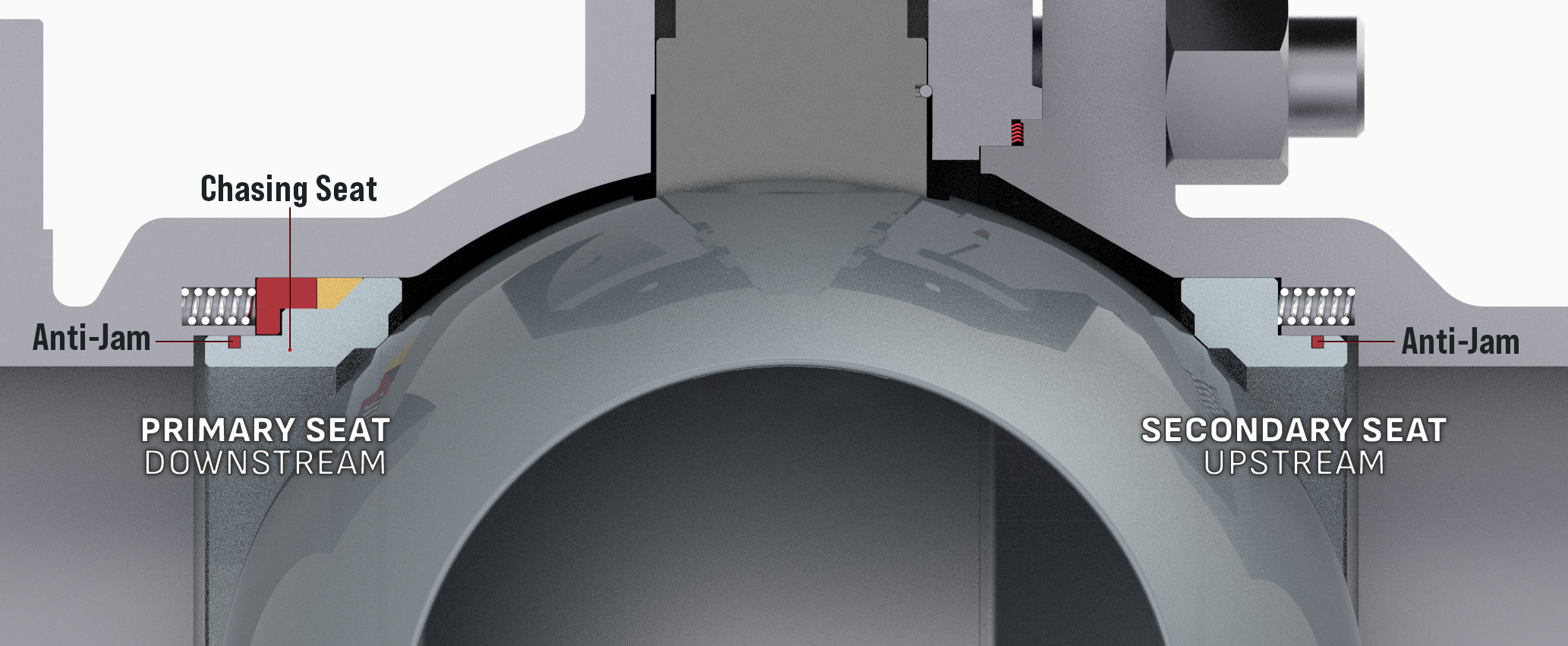

Sealing Directionality

Bidirectional (Preferred Direction)

End Connections

RF, RTJ (ASME B16.5) BW (ASME B16.25), SW (ASME B16.11)

Trim Materials

316SS, A286 Gr. 660 (Stem), Inconel 718

Other Materials Available on Request

Take a Look Inside!

Features & Benefits

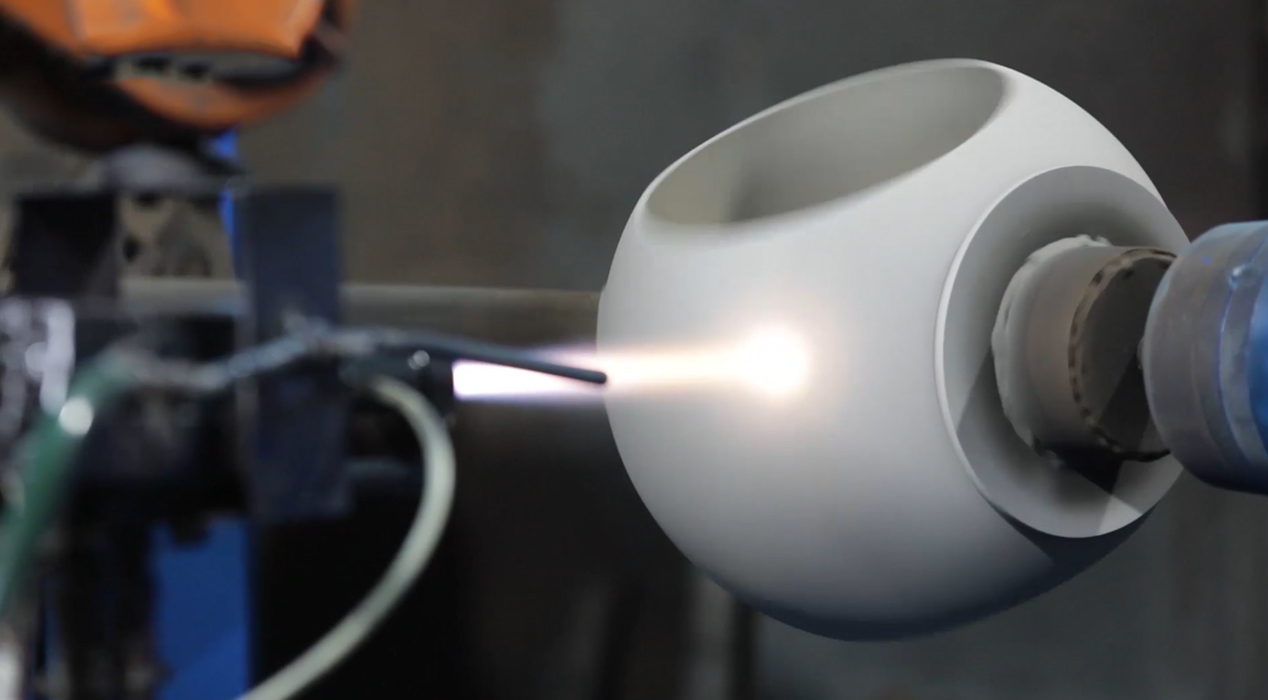

Advanced Coating Technologies

- HVOF coating with Chromium Carbide (Tungsten Carbide also available) is applied with state-of-the-art technologies to ensure long-lasting performance in the most severe conditions.

- QPQ Nitrided Trim is also available as an economical option for lower cycle, less challenging applications.

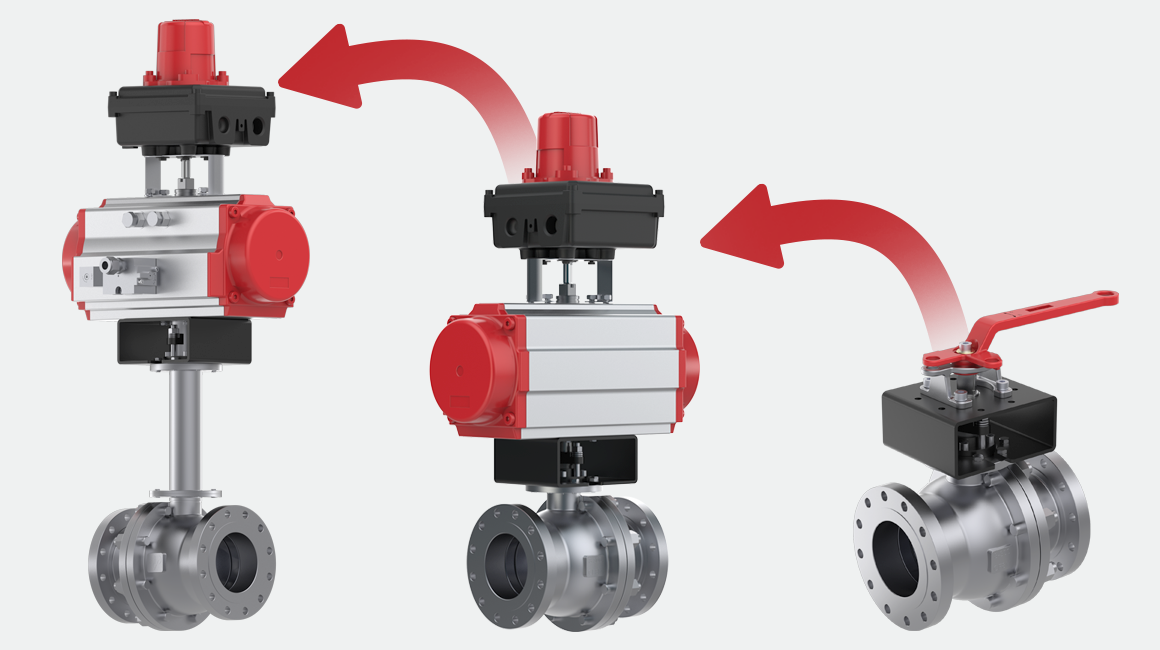

Quick Switch Module Design

Allows for easy modification of valve to manual, gear operator or actuators with off-the-shelf interchangeable parts

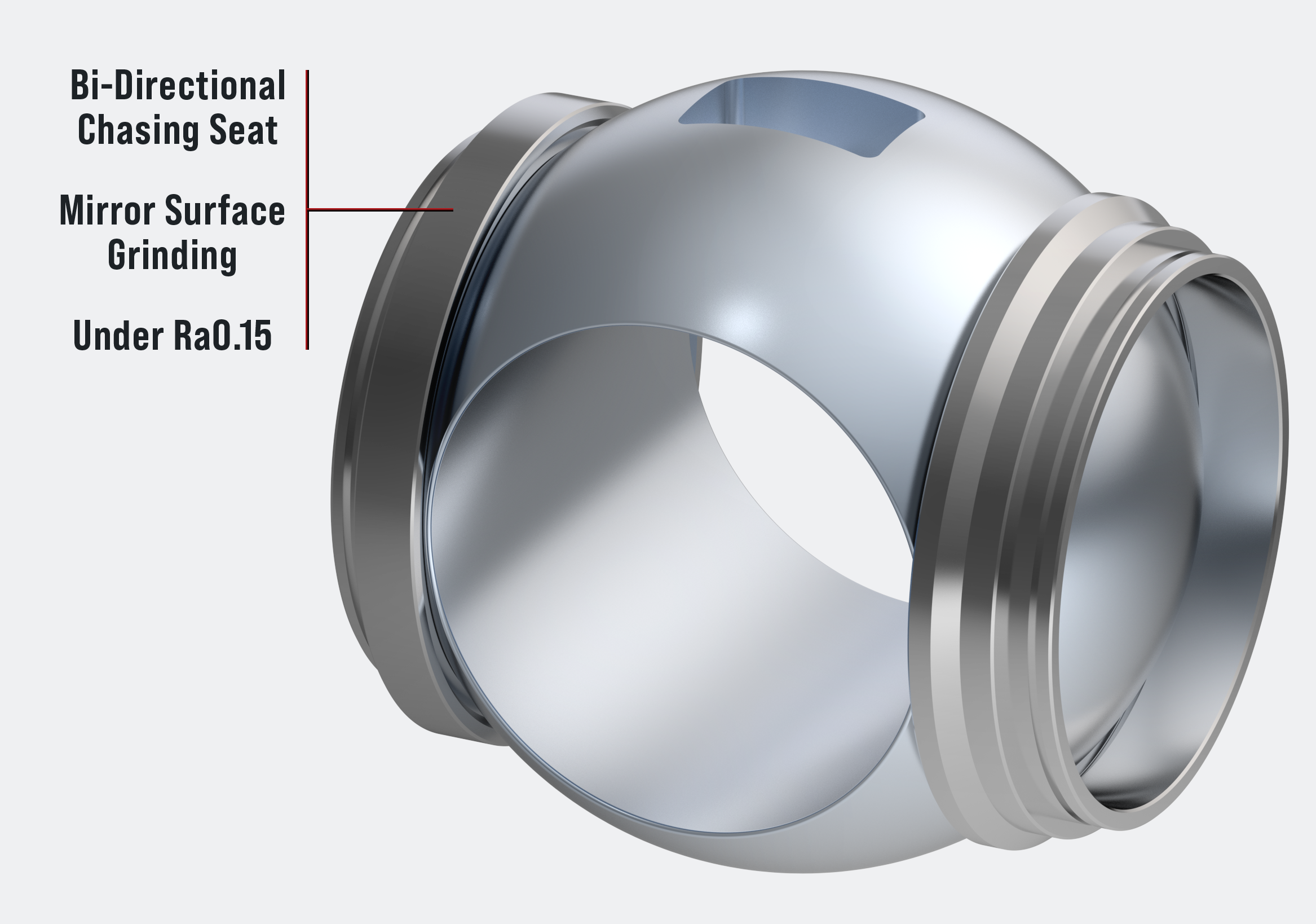

Robust Seat Design

Superior finishes and precise dimensional control combined with a robust seat design allows the JBFM to achieve reliable shutoff in a broad range of difficult applications.