JTEM SERIES

Metal Seated Butterfly Valve

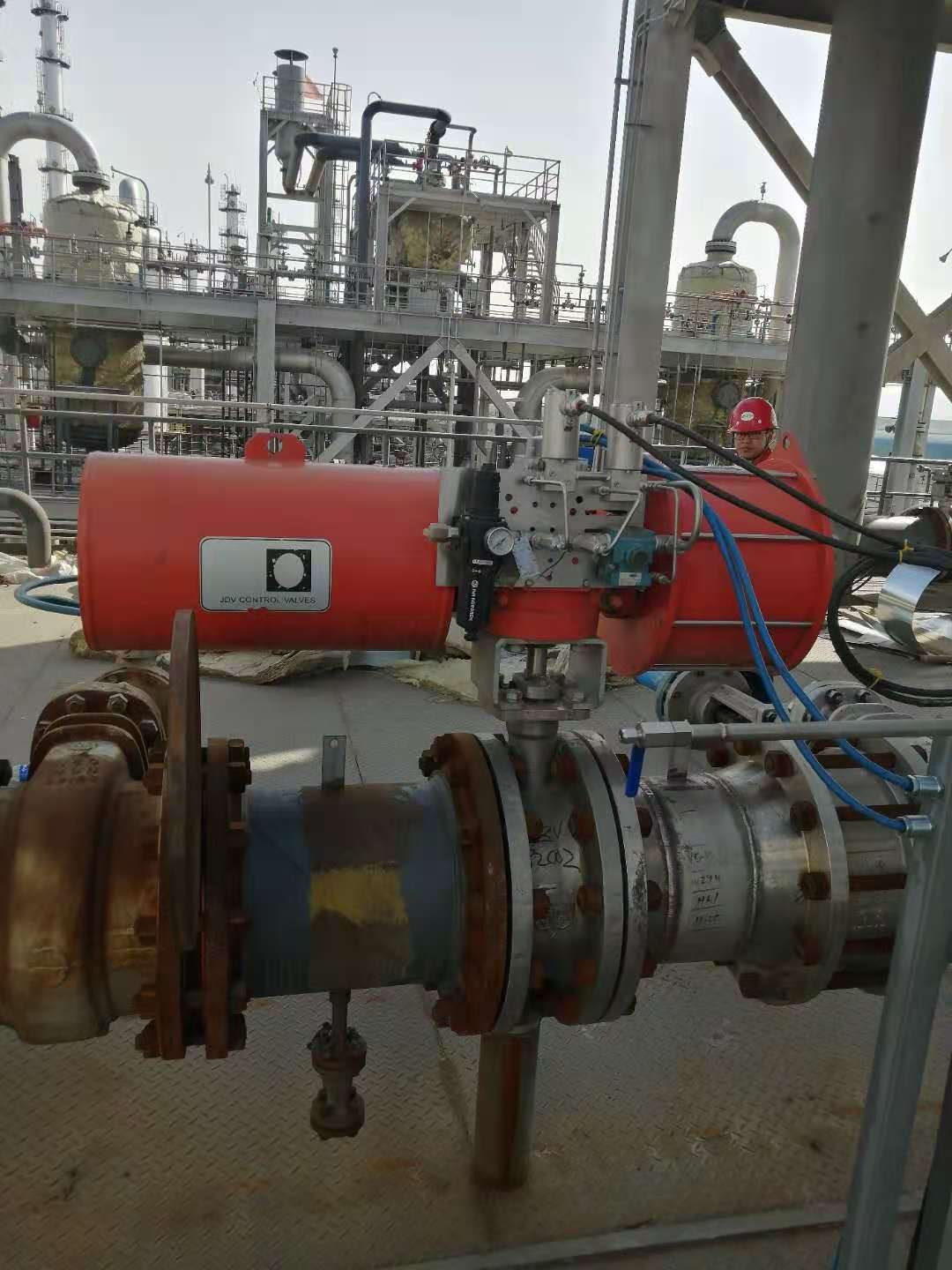

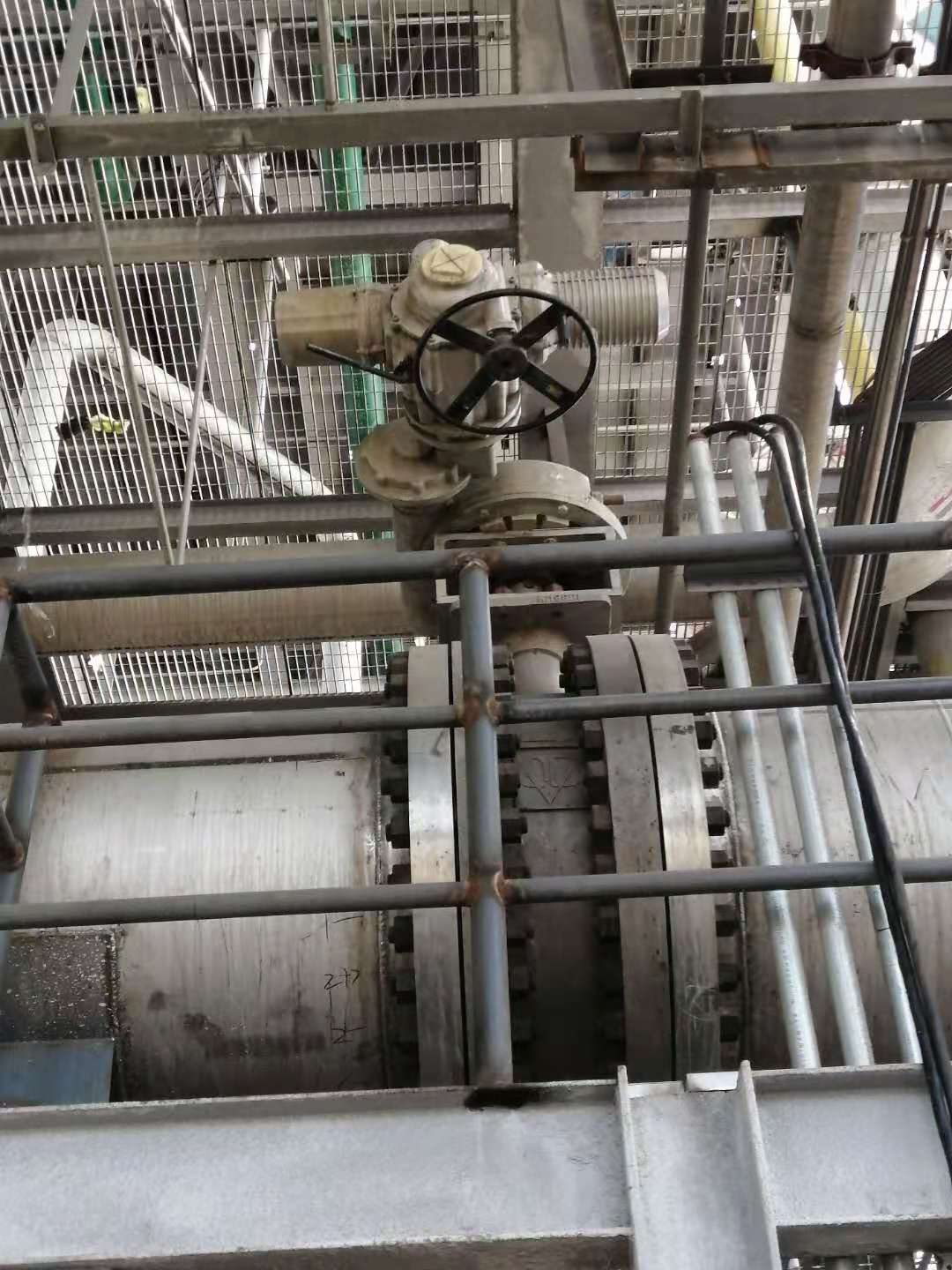

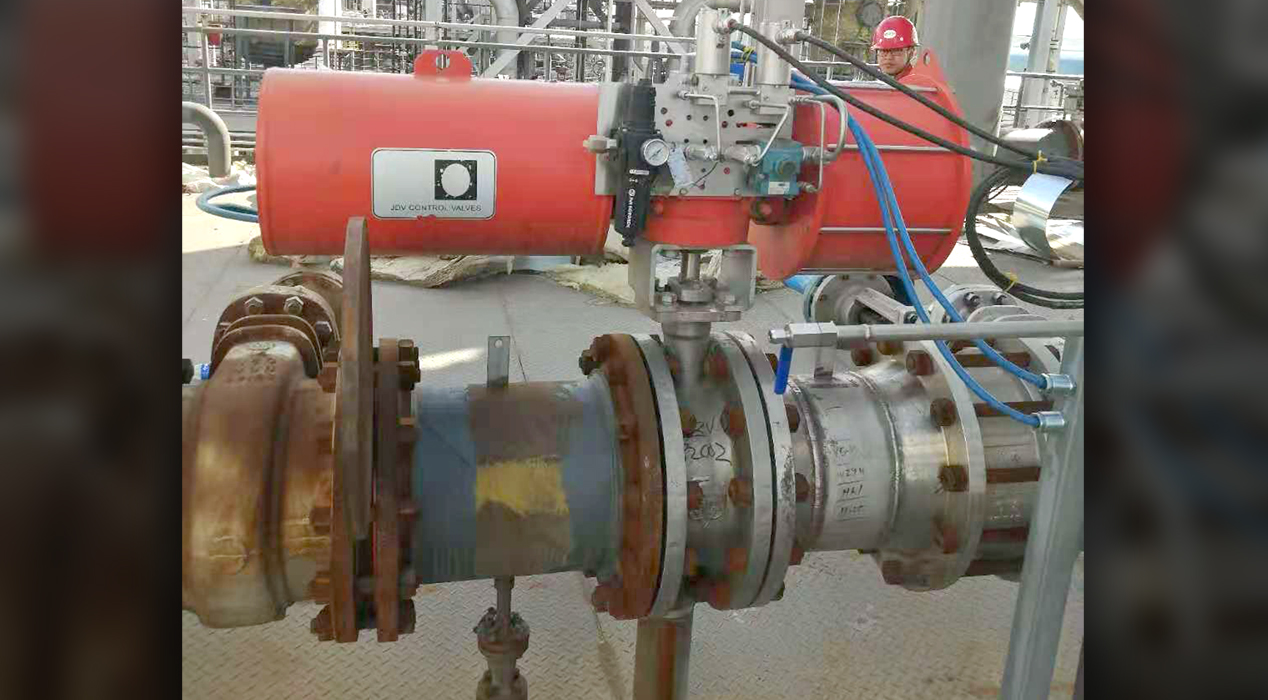

JDV is proud to offer the JTEM series Triple Offset Metal Seated Butterfly Valve. This valve combines an innovative sealing design with superior manufacturing and workmanship to present a unique value in the industry. The JTEM is ideal for applications such as abrasive media, high pressure drop, high temperature/thermal cycling, and cryogenic temperatures.

The JTEM series with its true metal seated triple offset technology gives it superior performance in these challenging applications compared to traditional wedge gates and laminated seat triple offset butterfly valves, at a much more attractive price than a typical metal seated ball valve. The JTEM series is solving challenging application problems across many industries. Let us solve yours next!

Specifications

JTEM Series Metal-Seated Butterfly Valves

Size Range

3″ – 48″

Pressure Ratings

ASME Class 150 through 2500

End Connections

Lug, Wafer, Short Pattern Flanged, Long Pattern Flanged (ASME B16.10)

Design Standard

API 609

Test Standard

API 598

Take a Look Inside!

Features & Benefits

True Metal-Seated Design

A unique scraper ring and solid metal seat provides superior longevity in abrasive and corrosive services.

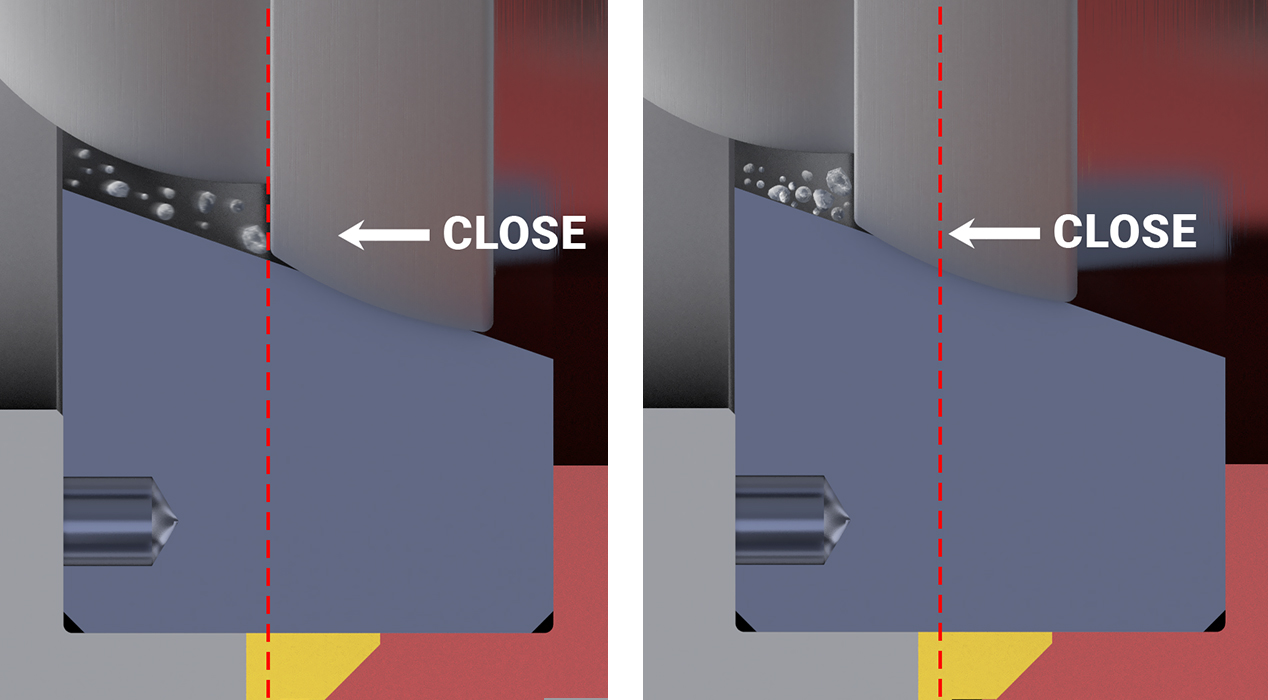

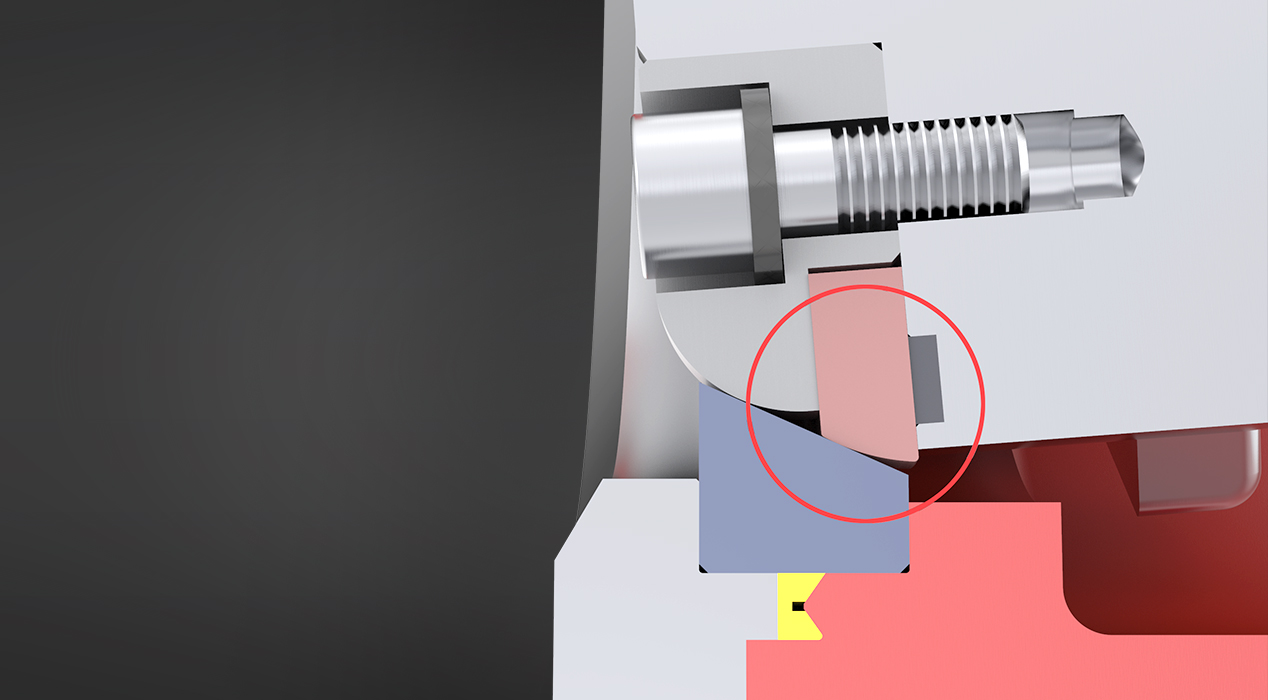

SlideSeal Technology

JTEM’s unique SlideSeal design has a unique scraper function that works to clean the seating area on closing thus removing solids or debris that could damage or clog the seating area. The seal ring slides into the seating area upon closing the valve. This provides 2 key advantages:

- The scraper function sweeps debris from the point of contact between disc and seat, providing superior sealing performance and repeatability in media containing solids, particulates, and debris.

- As the disc and seat wear, the sliding action and seal geometry allows the disc to continuously find an optimal point of contact for a tight seal. This ensures repeatable sealing over time. These advantages together allow the SlideSeal technology to provide better sealing than the typical point of contact seal. It helps to ensure bubble tight sealing and prolong the life of the valve even in the most severe of services.

Field Repairability

While traditional TOVs typically can have the seal ring repaired, those valves have a welded in seat that are not able to be repaired in the field. If there is any damage to the seat, they will need to be pulled out of line and repaired in a specialty shop, or completely replaced – costing you time and money. JDV’s JTEM valves feature a removable seal ring AND seat. Our design features alignment holes on the valve body and disc, and easy access to the replaceable parts without full valve disassembly. This allows for an easy field repair if the need should arise.

Advanced Stem Packing Design

The JTEM comes standard with a live-loaded packing gland, and API 622-compliant packing for best fugitive emissions performance, including in high temperature and/or thermal cycling applications.

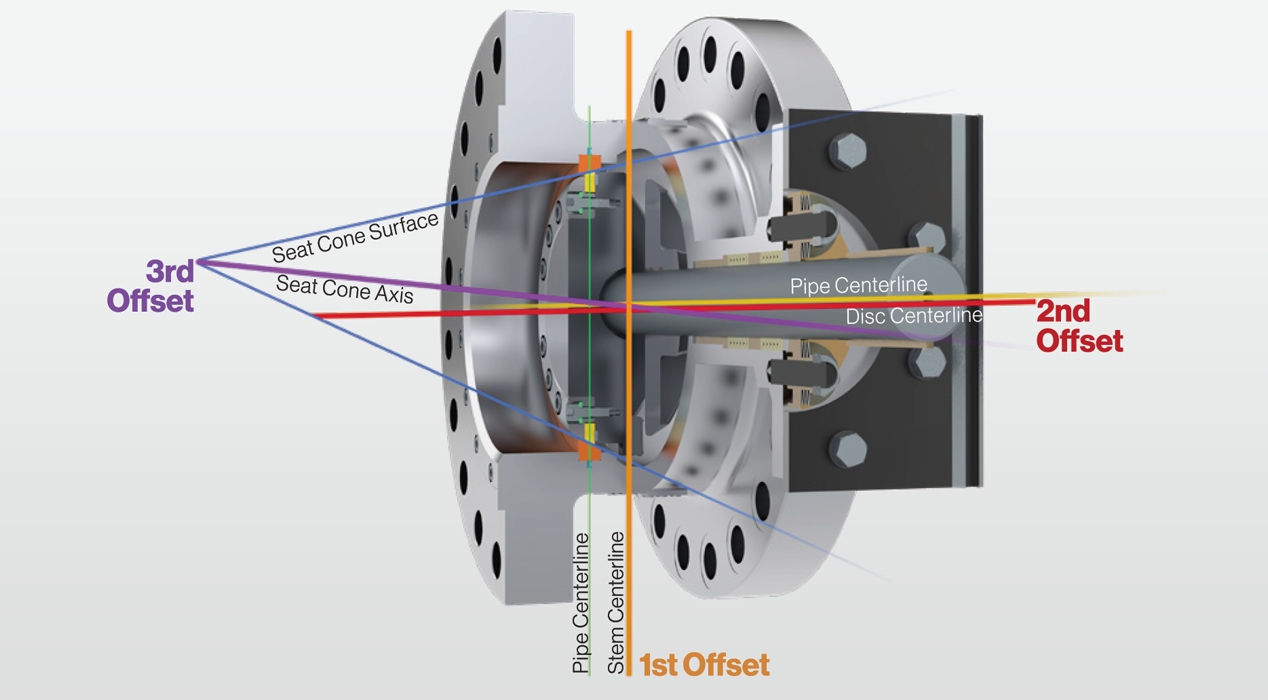

Triple Offset Geometry

JTEM’s innovative double inclined triple offset design inherits the advantages of the typical TOV design and optimizes them to provide the lightest torque, zero leakage performance, a prolonged life cycle, and an easy maintenance process.