JBFH SERIES

High Pressure Severe Service Metal Seated Ball Valve

JDV is proud to offer the NxGEN JBF Severe Service Ball Valve. These are the newest products in the JDV portfolio, and JDV has completed this new cutting edge product with Computer-Aided Drafting & Design, Finite Element Analysis, verified and validated by prototyping and extensive design testing in its Research & Development Center. The result is a robust, thoughtful, feature-rich design that we are confident will exceed the expectations of even the most demanding valve users.

Specifications

JBFH Series Metal-Seated Ball Valves

Size Range

1/2″ through 2-1/2″

Temperature Range

up to 1,200°F (650°C)

Design Standard

Valve Design: ASME B16.34

Valve Test: API 598

Actuator Mounting: ISO 5211

Body Materials

Carbon Steel: A105

Low Alloy Steel: F11, F22, F5, F9, F91

Other Materials Available on Request

Pressure Class Range

ASME 900, 1500, 3200, 4500 LTD

Sealing Directionality

Unidirectional

End Connections

Socketweld (ASME B16.11), Buttweld (ASME B16.25)

Trim Materials

410SS, Inconel 718, Gr. 660 (Stem)

Other Material Available on Request

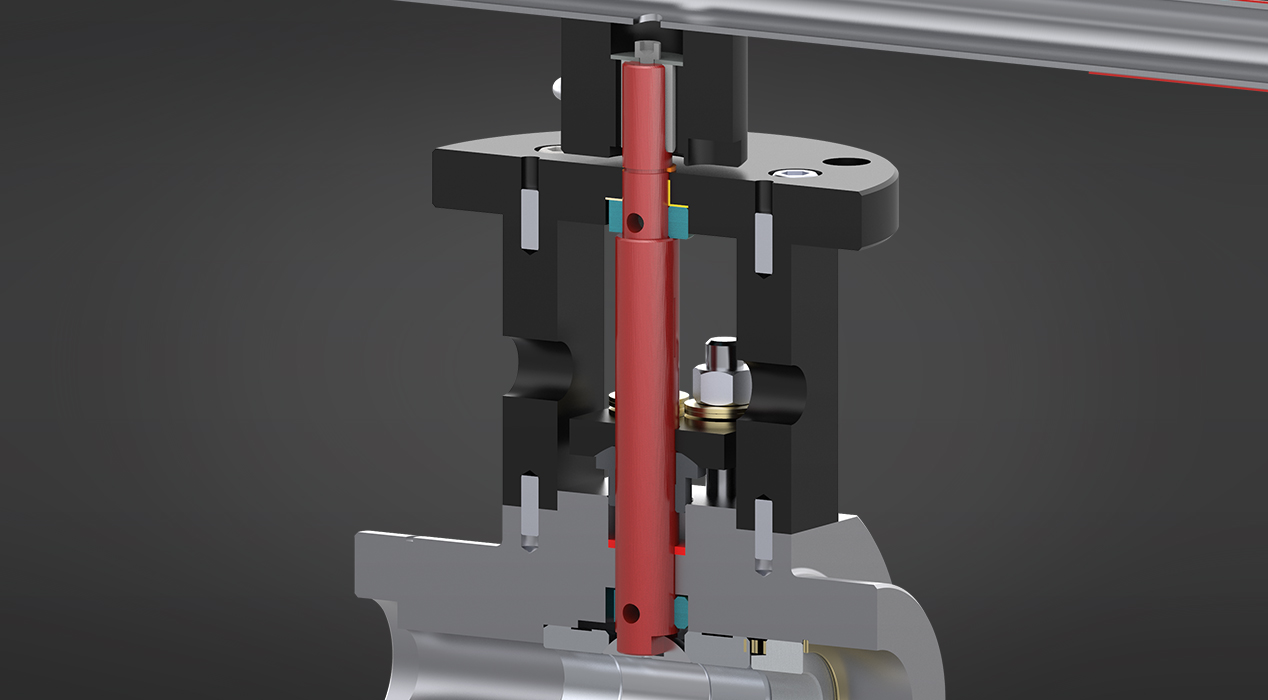

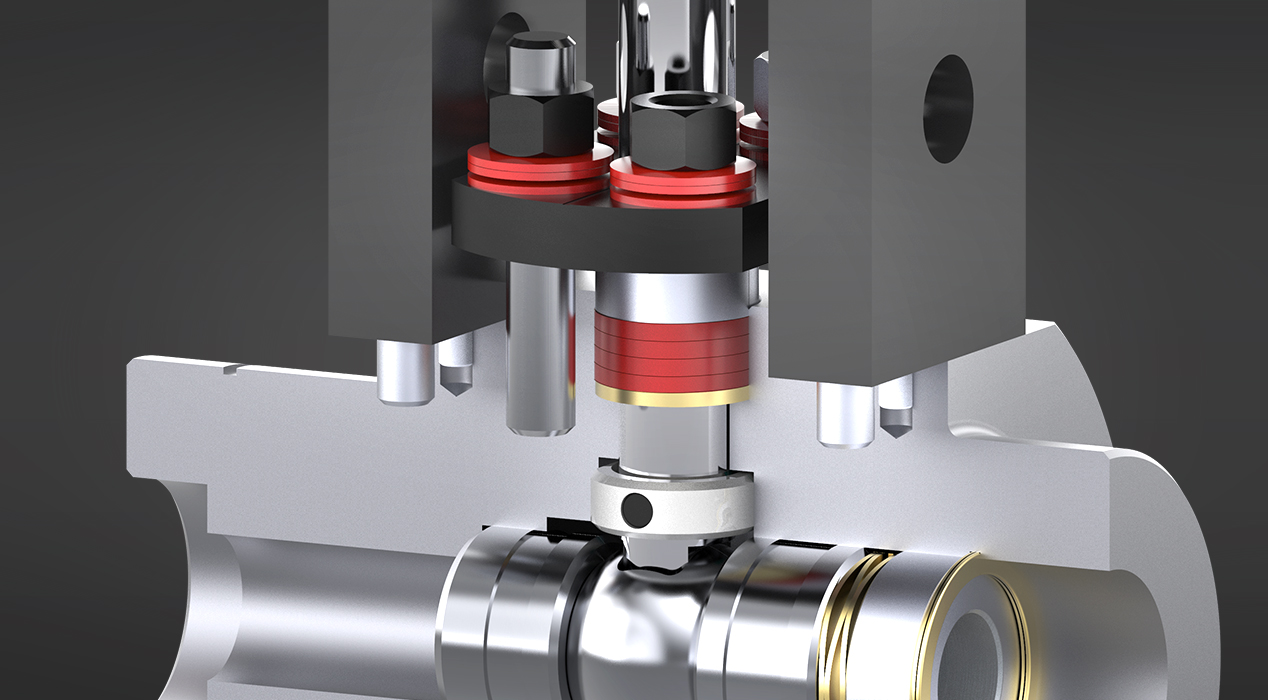

Take a Look Inside!

5 Year Warranty

JDV is pleased to offer an industry-leading 5-year warranty for our JBF Series ball valves.

JDV Model JBFL and JBFH metal-seated ball valves for the power industry are warrantied for 60 months after shipment from the factory or 48 months after installation in service, whichever occurs first. This warranty covers defects in material and workmanship only and not for consequences of improper installation or application and is limited to the value of JDV’s repair or replacement. It does not imply, nor authorize, any backcharges for unauthorized repair or replacement. This warranty is based upon the valves being utilized in services, and within pressure and temperature parameters, for which they are designed. Additionally, this warranty applies only to new, and not previously used, valves nor valves which have been modified in any way without the expressed written consent of JDV USA. This warranty also does not cover valves which have been stored improperly and subjected to elements that could be detrimental to the performance of the valves. Finally, this warranty is restricted to the value of the valves and does not include any consequential expenses. In the event of a warranty claim, it is JDV’s sole authority to determine, after analysis, whether to repair or replace in kind.

JDV Model JBFL and JBFH metal-seated ball valves for the power industry are warrantied for 60 months after shipment from the factory or 48 months after installation in service, whichever occurs first. This warranty covers defects in material and workmanship only and not for consequences of improper installation or application and is limited to the value of JDV’s repair or replacement. It does not imply, nor authorize, any backcharges for unauthorized repair or replacement. This warranty is based upon the valves being utilized in services, and within pressure and temperature parameters, for which they are designed. Additionally, this warranty applies only to new, and not previously used, valves nor valves which have been modified in any way without the expressed written consent of JDV USA. This warranty also does not cover valves which have been stored improperly and subjected to elements that could be detrimental to the performance of the valves. Finally, this warranty is restricted to the value of the valves and does not include any consequential expenses. In the event of a warranty claim, it is JDV’s sole authority to determine, after analysis, whether to repair or replace in kind.

Features & Benefits

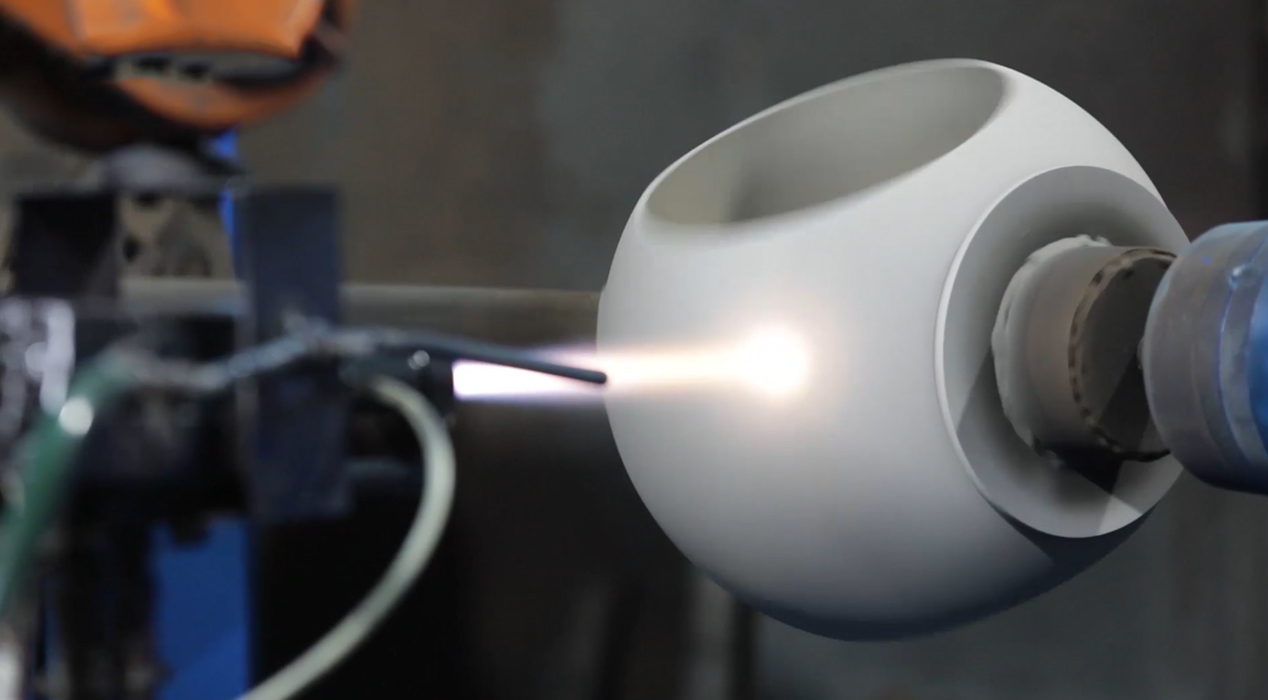

Advanced Coating Technologies

- HVOF coating with Chromium Carbide (Tungsten Carbide also available) is applied with state-of-the-art technologies to ensure long-lasting performance in severe conditions.

- Spray & Fuse technology provides superior wear resistance and a better bond to the substrate material due to its metallurgical bond.

Full Spherical Lapping

- Full spherical lapping laps the entire ball to the seat which prevents the coating thickness from being compromised as during traditional one-sided lapping techniques.

Oversized One-Piece Stem

- One piece quarter turn non-rising stem does not deteriorate packing and minimizes hysteresis when adapting to actuation. Fully-retained pins are contained and hardened to meet ASME B16.34 blow-out proof stem requirements.

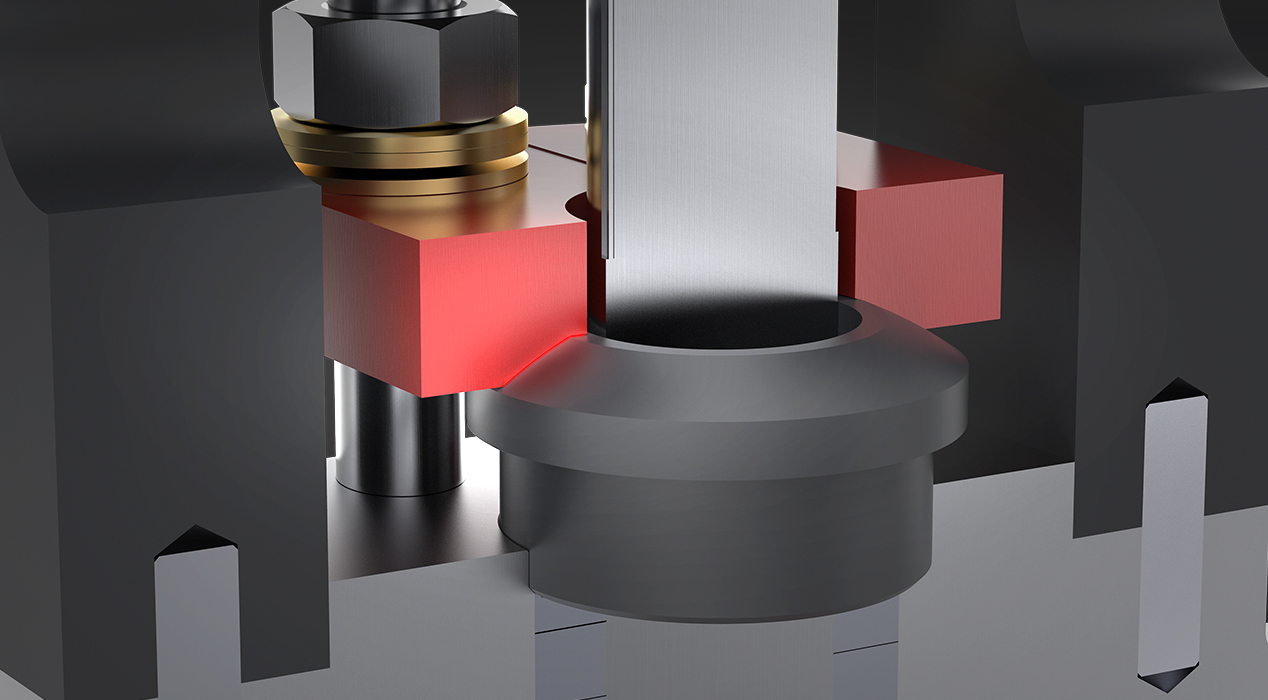

Articulating Gland Flange

- The spherical gland flange and packing follower allows for equal distribution of packing and is live loaded eliminating the need for routine packing adjustments.

Live-Loaded Packing

- Live loaded packing ensures continuous load pressure through thermal cycles. API 622-compliant packing set including braided wiper rings combined with die-formed graphite rings provide reliable sealing and longevity under constant load.

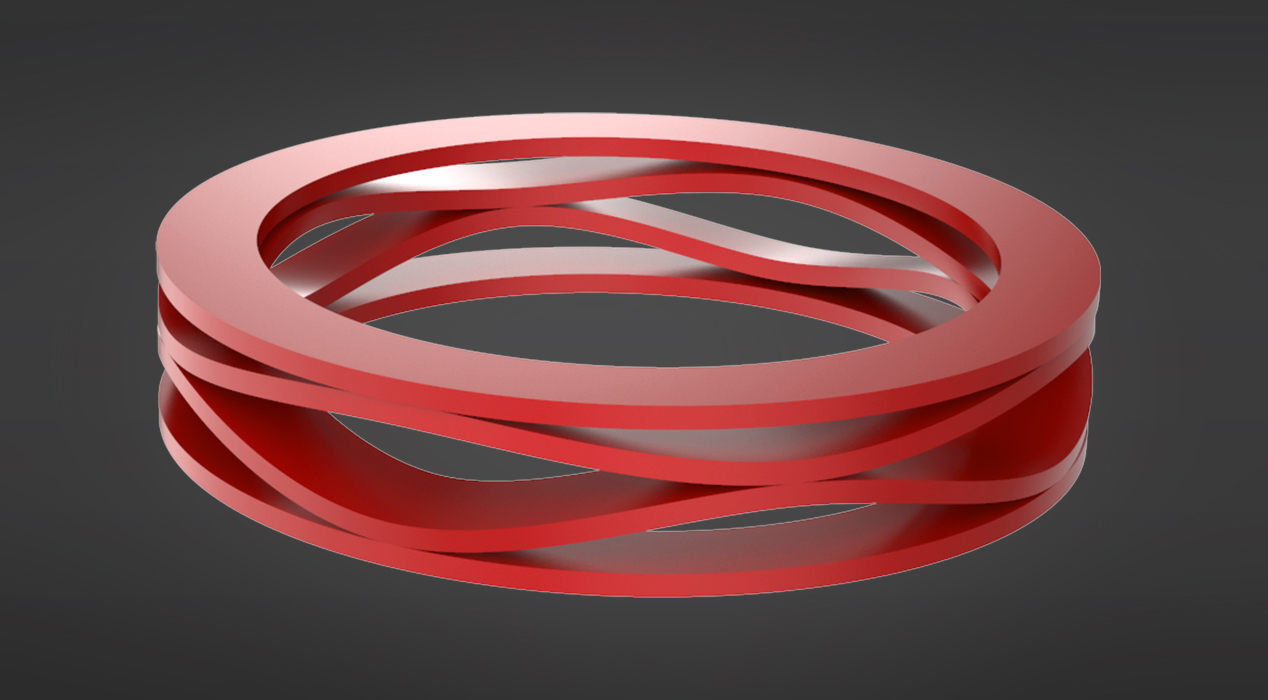

Wave Spring

- Wave spring reduces the risk of error in assembly and delivers a predicable performance, minimizing load variances both outperforming and lasting longer than a

standard Belleville spring.