JBFX SERIES

Large Diameter Severe Service Metal Seated Ball Valve

JDV is proud to offer the NxGEN JBF Severe Service Ball Valve. These are the newest products in the JDV portfolio, and JDV has completed this new cutting edge product with Computer-Aided Drafting & Design, Finite Element Analysis, verified and validated by prototyping and extensive design testing in its Research & Development Center. The result is a robust, thoughtful, feature-rich design that we are confident will exceed the expectations of even the most demanding valve users.

Specifications

JBFX Series Metal-Seated Ball Valves

Size Range

3″ through 12″

Temperature Range

up to 1,200°F (650°C)

Design Standard

Valve Design: ASME B16.34

Valve Test: API 598

Actuator Mounting: ISO 5211

Body Materials

Carbon Steel: A105

Low Alloy Steel: F11, F22, F5, F9, F91

Other Materials Available on Request

Pressure Class Range

ASME 900, 1500, 3200, 4500 LTD

Sealing Directionality

Unidirectional

End Connections

BW (B16.25) – Standard, Other end connections such as flanged, hub ends available on request

Trim Materials

410SS, Gr. 660 (Stem), Inconel 718, other materials available on request

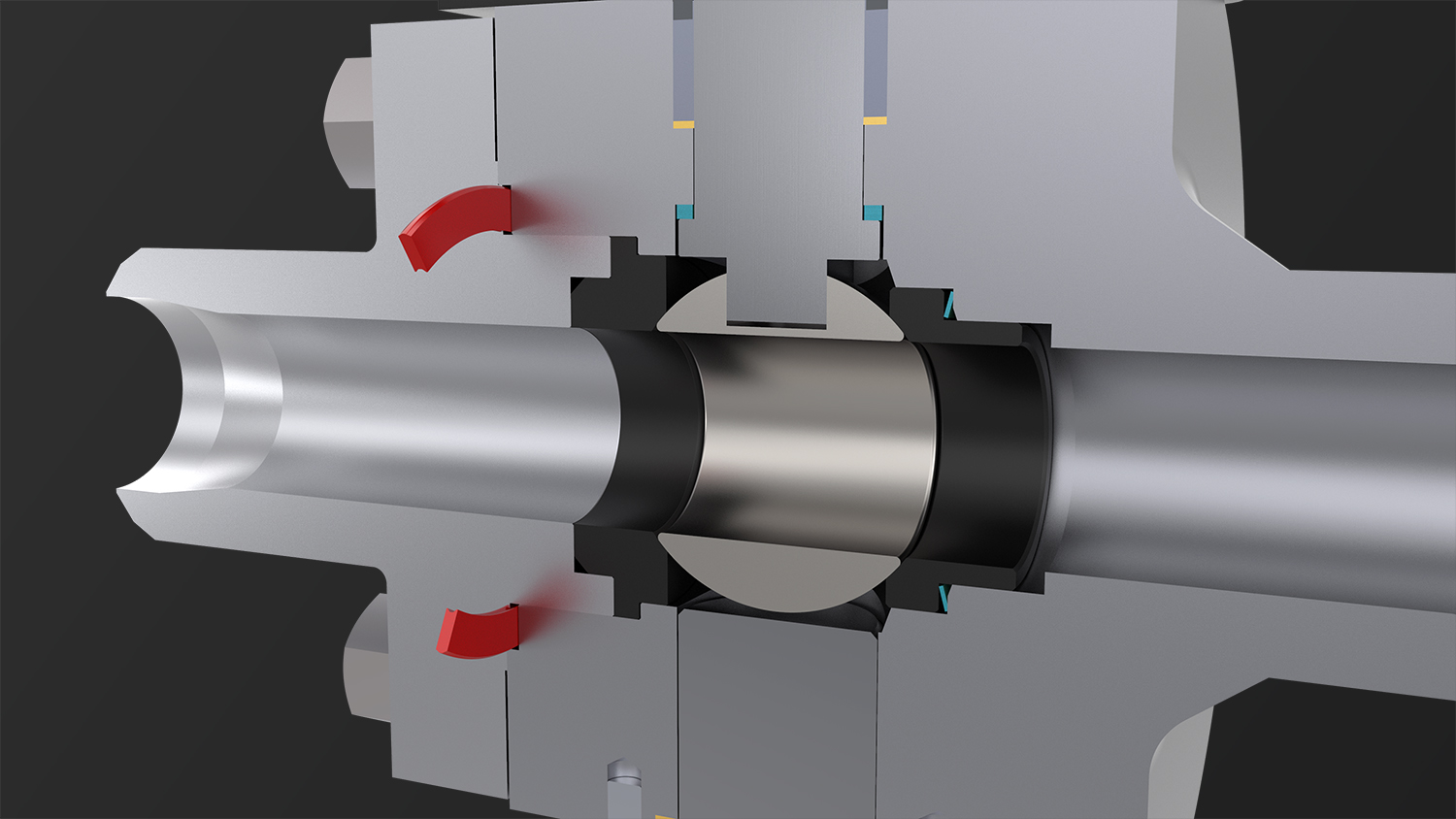

Take a Look Inside!

Features & Benefits

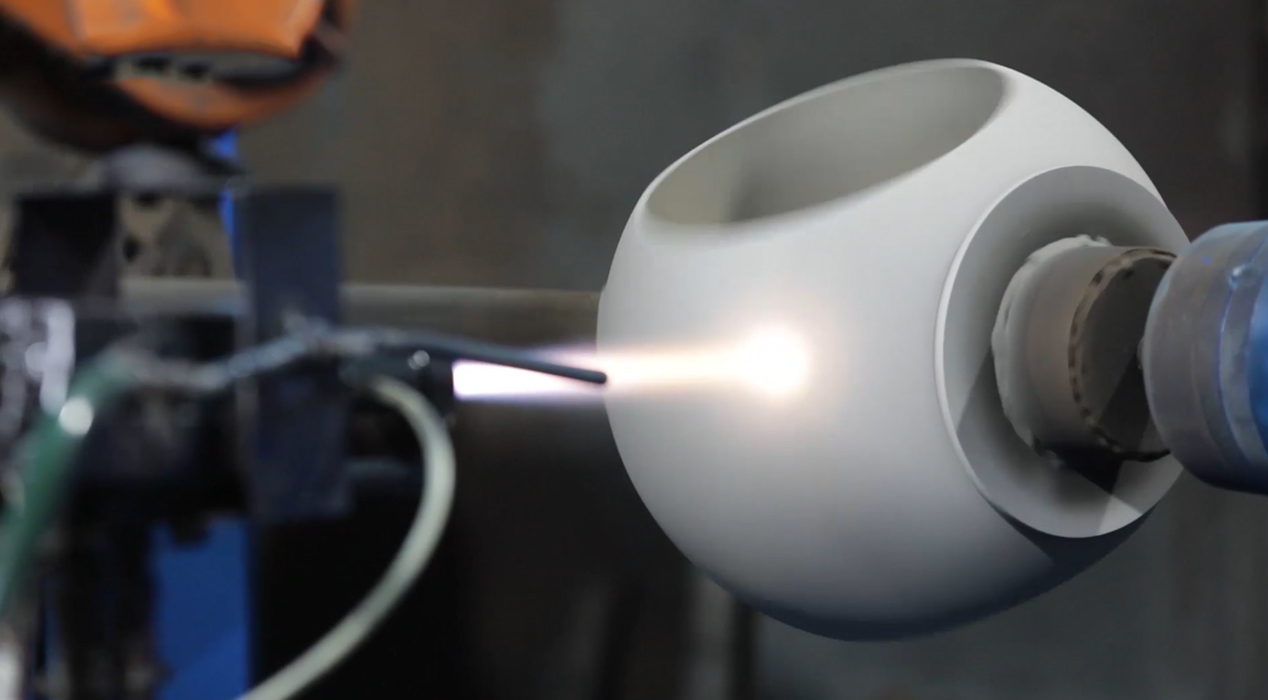

Advanced Coating Technologies

- HVOF coating with Chromium Carbide (Tungsten Carbide also available) is applied with state-of-the-art technologies to ensure long-lasting performance in severe conditions.

- Spray & Fuse technology provides superior wear resistance and a better bond to the substrate material due to its metallurgical bond.

Full Spherical Lapping

- Full spherical lapping laps the entire ball to the seat which prevents the coating thickness from being compromised as during traditional one-sided lapping techniques.

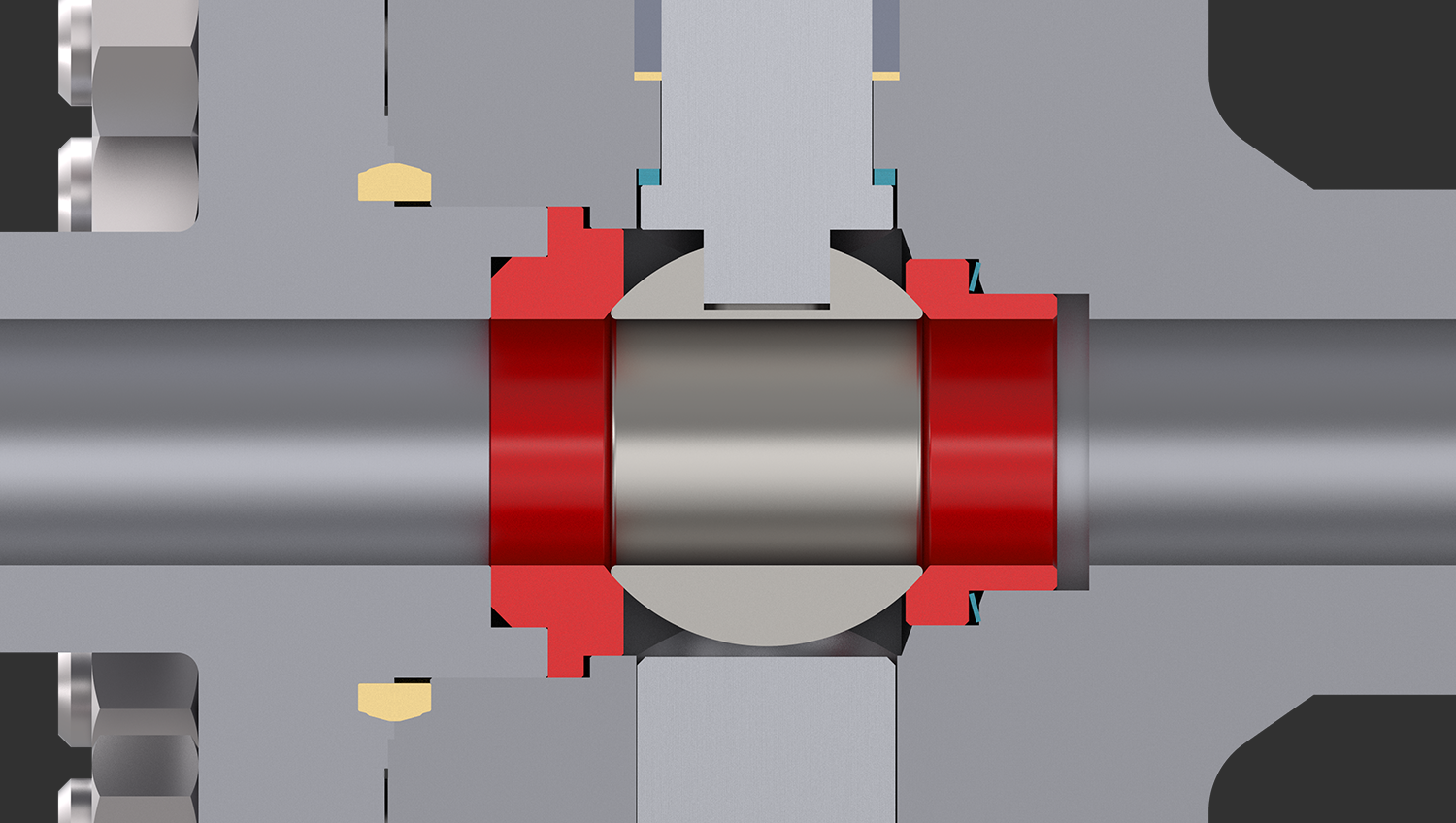

Spiral Wound Gasket

- Class 900-1500 are equipped with spiral-wound gaskets for ease of maintenance

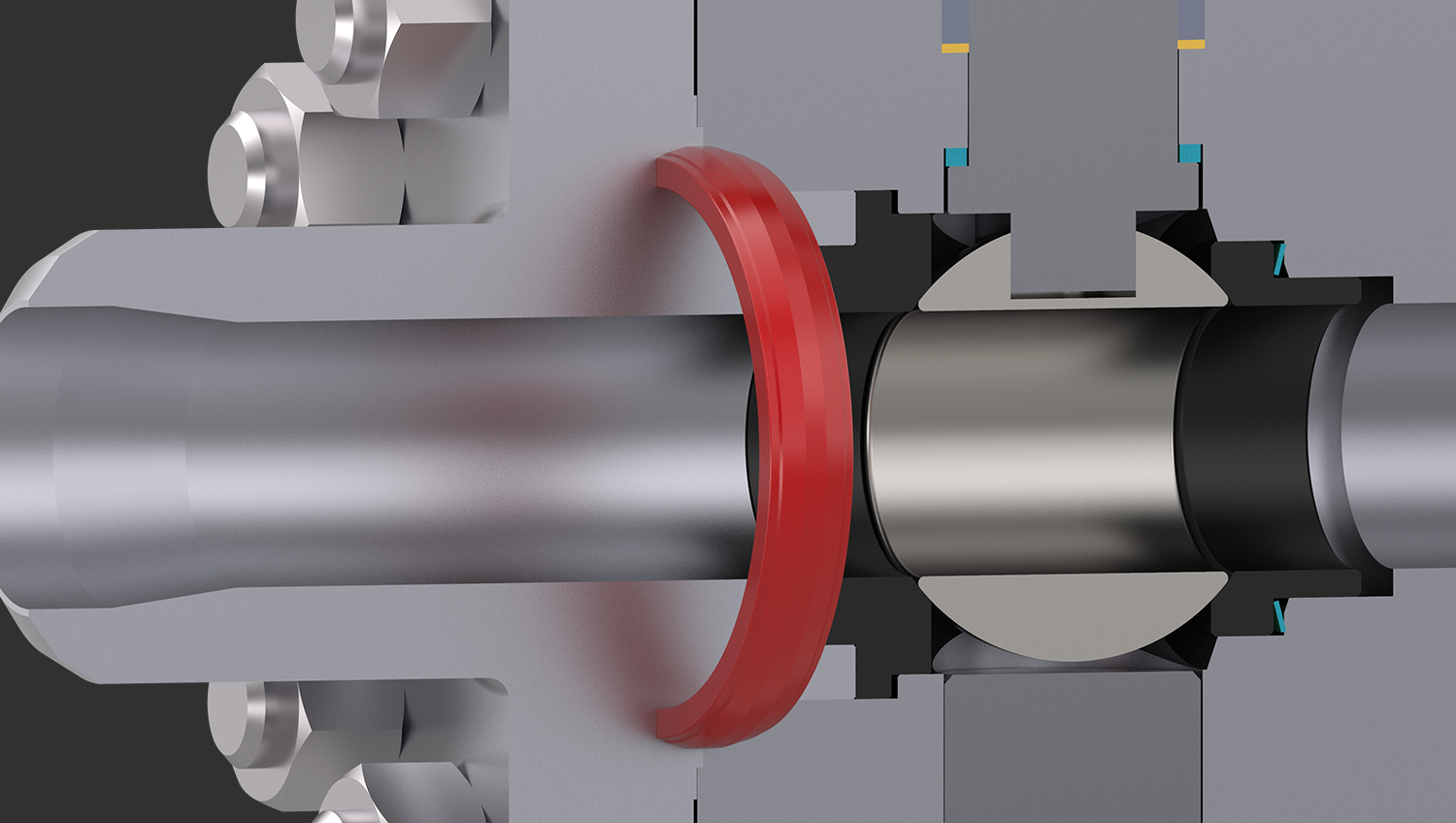

Metal Delta Ring

- The delta ring is engineered to replace O-rings for soft sealing on ball seats, adapting to varied project needs.

- Metal delta ring is for class 2500 and higher

Flanged Seat Design

- With our HVOF coating technology, valves are resistant to the attack of abrasive magnetite and ferrous oxides that may be seen in the steam flow.